Updates are more for my own blogging so that I can kind of keep track...

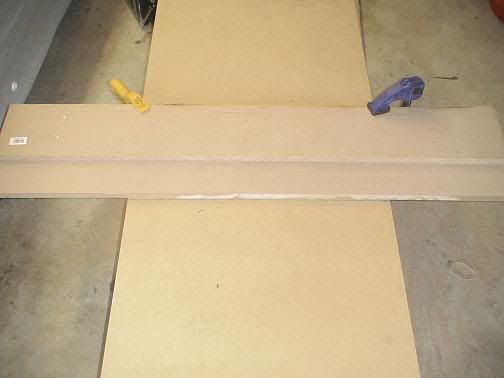

Saturday. Make a sawboard (as seen in the woodworking forum). and get the template cut

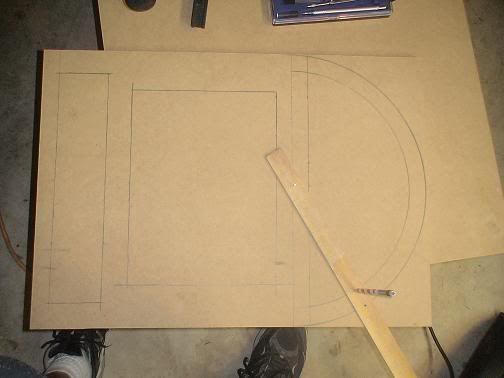

Practicing my drawing skills on the template. Like my arc maker? Wooden rulers are great.

Cutting the template out

I donít have a circle jig, but I do have the attachment for my dremmel. Might as well try it out. It worked fairly well.

Time to make the frame parts.

I did the same thing on both the front and back. I got farther away from my arc cut the farther into it I go, and the scraps show it.

Set up for cleaning the edges.

And away we go.

All done

I donít have foerstner blades, but I do have a hole cutting kit.

They sure make a mess

Monday. Cut a bottom, then make a couple spacers out of the wood I have around. I would have liked a bit larger pieces, but I use what I haveÖ.

Time to put the whole thing together. Its hard to hold everything alone, ainít it?

Itís ready.

The first side 1/8 sheet goes on. Much chaos entails. I hope it holds.

Home

Home Help

Help Search

Search Login

Login Register

Register

Send this topic

Send this topic Print

Print