I ended up finding some 1/8th plywood for the back, and I am still working on it, but I have a little more progress finally.

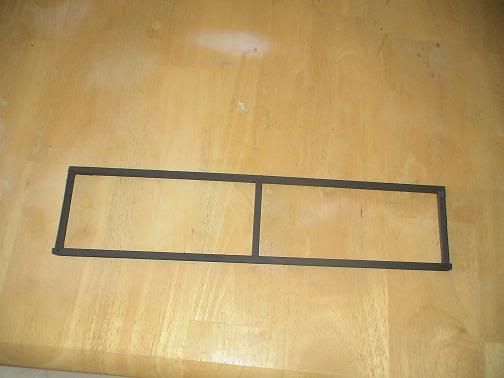

I went with a 1/4 frame for the speaker grill. I didn't bother with the metal mesh, as I don't like how they look as much as plain speaker cloth.

I used some speaker cloth and some spray adhesive that I had to cover the frame and used a couple carpet tacks to hold it onto the panel a little better, though I doubt it would have moved.

I then mounted the glass

Followed by the rest of the screen, and the motherboard spaced from it as I tested earlier.

I have the front ready to go other than artwork. Really wish I was better at that stuff so I could have gotten that out of the way as well before assembling it, but oh well. I'll likely change it once the GF sees it anyway, right?

I do notice that the screen opening is just a little bit too big, and you can see a little of the silver strip along the edges. ah well.

The money shot.

I'm working on something for the back panel as well before I mount the shell to it that should be really snazzy.

To Do listFigure out what parts to get and order a FrontX panel

Finish back of shell to handle back panel idea.

Mount front panel to shell.

add laminate

Make Tmolding slot

Add fan

Add speakers

Add light

Add light box

Add slots for USB connections on the side

Find a copy of XP and reformat new drive and hope the IDE <=> SATA adapter I found works

Mount HD

Try to understand how to replace the start button, make an external speaker switch, power stuff, and other assorted wiring.

Make heat vents like drawfull did on his. (wish I had a router template tool like he showed...)

Finish marquee

Mount back

Work on software

15 other things I forgot.

Home

Home Help

Help Search

Search Login

Login Register

Register

Send this topic

Send this topic Print

Print