Cheers DaOld Man, duplicate away!

Had a better day today, got a lot done in a couple of hours.

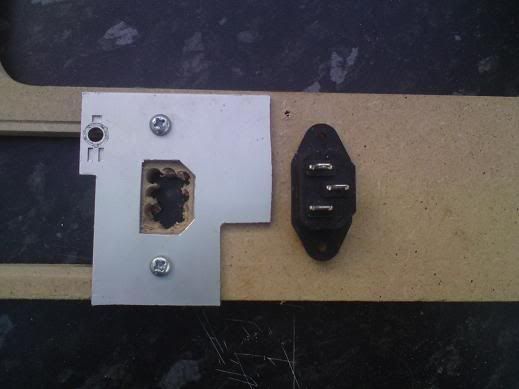

I made a template to cut out a relief for the power inlet and the used that to route the opening:

I then used some carpet tape to stick the new piece of 3mm acrylic to the MDF back panel and cut out the openings (no cracking this time

):

Once that was done I used one of the I/O plate templates to cut out the acrylic so that the plate will be flush with the acrylic:

I then marked the mounting hole positions and then used the other template to cut out the relief in the MDF for the components:

I recycled the FUBAR acrylic from my 1st attempt and used it to cover the back door and I drilled a hole for the cam lock:

Couple of assembled pics:

I was soo tempted to remove the protective film but I still need to polish the routed sections. I have a novus kit on the way over from the states so I should be able to get it the back completely finished then.

I also got a new toy this week

Heavy duty 650w (0.87HP) single phase pillar/press bench drill. It has a 16mm cluck on a MT2 taper which is handy as ill be able to use taper shank drills as well as straight shank. It also has a rack and pinion crank table which it great. ---fudgesicle--- me the thing is heavy though! Its 86kg (13.5 stone)! I could barely lift the head on it own when assembling it.

I got it off ebay for an absolute bargain price of £142

I bought a smaller pillar drill from machine mart last week but it was crap, you could stop the spindle with your hand (not advisable

). This one is much more powerful and should hopefully last me forever.

This is it next to the one I had been borrowing off a friend:

That's it for today, I'm off to play some Call of Duty 5

Home

Home Help

Help Search

Search Login

Login Register

Register

Send this topic

Send this topic Print

Print