I've seen another builder attach four small brackets to each mounting hole on the joystick plate, cut a square opening, and attach them to the sides around the opening.

That sounds like a variation on the top mount method.

Seems like it would be dfficult to conceal the hardware and make it look good.

To my eyes it was more to ensure stability in MDF

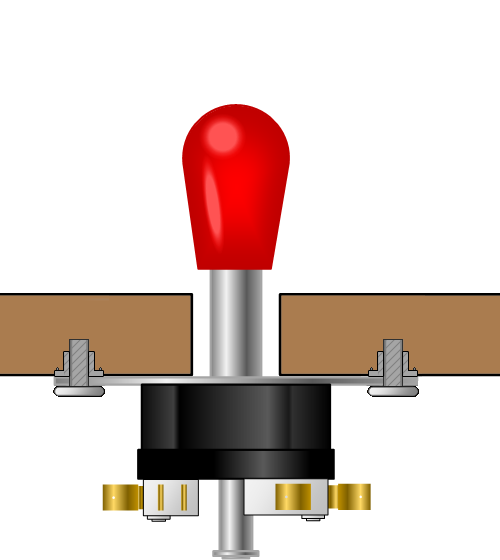

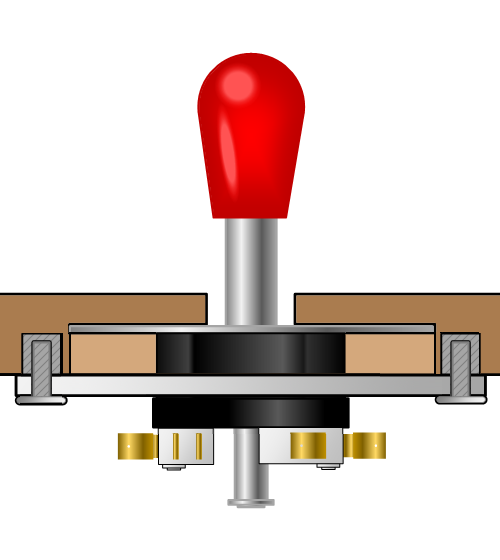

Threaded inserts do make it possible to remove/repair/replace joysticks without pulping screw holes in MDF, but the purpose of the "Under mount (support blocks)" method is to mount the stick closer to the surface than you can with this "Under mount (threaded inserts)" method.

- If you route a pocket for the mount plate you have to leave enough depth for the threaded inserts and screws so the screws don't poke through the surface of the CP.

- If you have a 0.75" CP and route a 0.25" pocket, that leaves 0.5". The threaded inserts from GGG are 0.4" tall, leaving you with 0.1" from the top of the threaded inserts to the surface of the CP. That's why the "Under mount (support blocks)" method is the better choice IMHO.

The FAQ version would work but as the stick already has a plate, it would not gain any height.. unless what you're saying is Gilrock's method moved the plate more toward the bottom.

You're missing the whole point of the "Under mount (support blocks)" method.

- The stick does come with a plate, but in this method that's not how you fasten the stick to the CP.

1. Route a pocket for the stick on the underside of the CP.

2. Put the stick in the pocket. It is now closer to the top surface of the CP than it would have been without the pocket and the handle is higher above the CP. That's what you want, right?

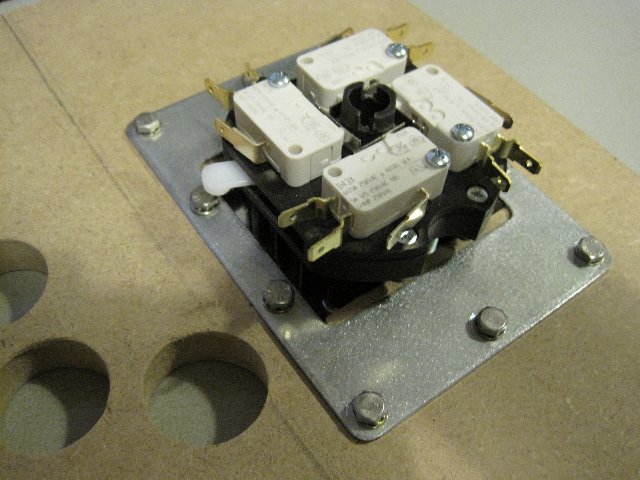

3. Add support blocks (or cylindrical spacers in Gilrock's version) that come level with or slightly past the underside of the CP.

4. Fabricate a plate or flat bars and put the threaded inserts (4 is enough, 10 is overkill

) in the full-thickness part of the CP

outside the pocket. If the pocket is loose, mount the stick to the support blocks and the support blocks to the fabricated plate/bars so the stick doesn't wiggle around in the pocket.

The fabricated plate is the thick one that the screws pass through in this diagram.

Scott

Home

Home Help

Help Search

Search Login

Login Register

Register

Send this topic

Send this topic Print

Print