Thx Dude,

Your explanations were great. Too bad I already took the time yesterday to painstakingly measure everything over and over to draw mine battens.

I do plan on laminating the inside of the cabinet. I don't understand why it is necessary to rout out the laminate for the pine batans. Is it because the pine will not adhere to the laminate with the contact cement?

Also do I need to be exact when making the joystick recesses or is just like battens? (just need enough points of contact)

Also do I need to use a straight edge bit. I think its also called a Mortise bit?

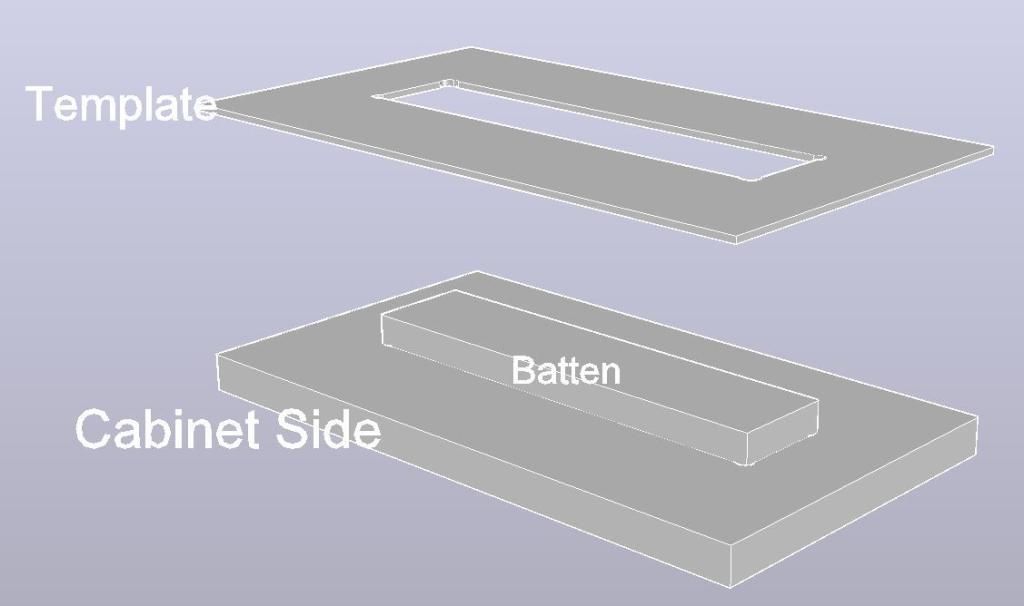

Drawing the battens in jig accurately is good, and if you are going to cut recesses into the laminated inner walls of the cabinet to put the battens in then cutting the jig carefully and accurately is good too. The purpose of routing recessed pockets into the cabinet for the battens is exactly what you thought. Laminate is only meant to be glued on one side so the smooth side that is meant to be seen doesn't take adhesive well. You could just screw the battens in place without cutting away the laminate but in most projects the glue is actually more important than screws so routing away the laminate and then gluing and screwing the battens would be the best bet. With that in mind, now cutting the jig cleanly becomes more important because you will end up cutting the exact shape of the jig holes into the cabinet and even if they are on the inside of the cabinet you will want them to look clean and fit the battens snugly.

The same logic applies to the joystick recess, it's part of the cabinet, not just a tool that you are done with once the cabinet is built so you might as well take the time to cut it nicely.

To do all these cuts I suggest that you carefully cut the shapes out of a jig (even for the joystick, cut a jig with the shape of the mounting plate) and then use that jig with a

top-bearing router bit to cut your recesses. Here is a youtube vid that shows the process with a top-bearing bit that should help you get an idea of what I'm describing.

You can also use the top-bearing bit as a straight edge bit if you want to do some freehand routing of recesses so you shouldn't need straight cutting bit.

You have a few options to deal with the roundness of the router bit not allowing sharp corners. You can go in after the routing has been done and use a chisel to clean up the corners, you can round the corners of your battens so they fit into the rounded corners of the recess, or you can do what is called a dog-bone corner by cutting a notch at each corner of your jig that is big enough for the router bit to slip into it leaving room for the square block of wood to fit after the recess is cut. The last option is the least work if you are doing a bunch of parts like this but it does leave little unfilled curved bits at the corners. Dog-bones usually show up on things that have been CNC cut so that there is very little hand work required after the cuts but with a template it can be useful too. Here is what that looks like.

Home

Home Help

Help Search

Search Login

Login Register

Register

Send this topic

Send this topic Print

Print